Magna Benefits from Nidec Arisa System.

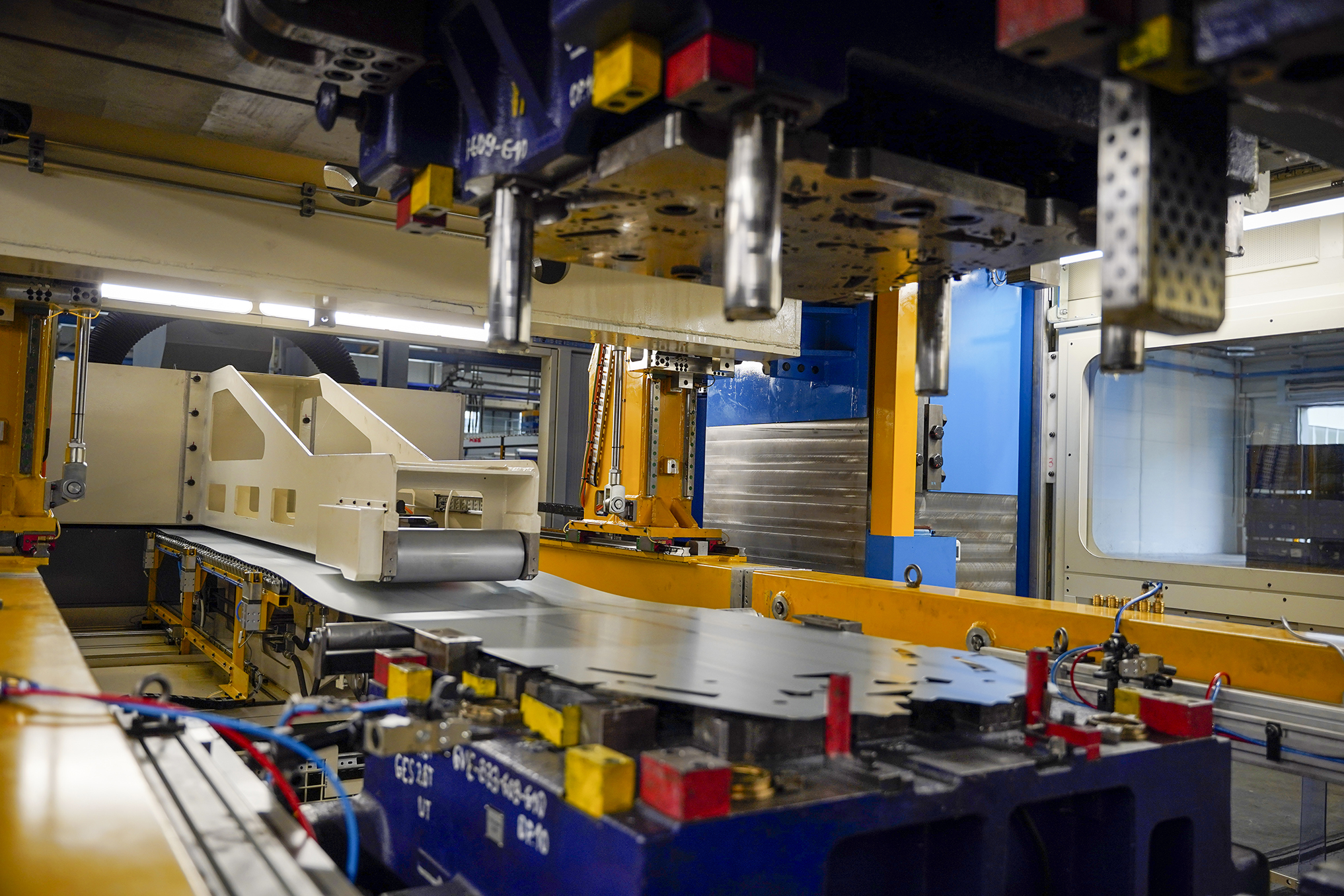

A recently-installed Nidec Arisa 1600-ton servo press, microfeeder, rolling bolsters, and High Dynamic Transfer has helped to increase productivity at the Magna Automotive Stity stamping plant.

Located in the Stity, Czechia, Magna Automotive Stity is part of the global Magna International, one of the largest automotive suppliers in the world with 174,000 employees in 351 manufacturing locations.

The Magna Automotive Stity Division includes two production plants in the Czech Republic with 500 employees, producing parts for the Skoda Automotive company along with Volkswagen, Mercedes Benz and others.

General Manager Martin Klein said Magna Automotive Stity maintains its leading position as a valued supplier because of an emphasis on efficiency.

“We have similar goals as most suppliers, and that is to produce as efficiently as possible with minimal downtime,” he said. “Our benefits generally include a long-term stable team, a friendly team and an emphasis on a clean working environment.”

And according to Machine Technician Miroslav Tejkl, their newest press line contributes to increased efficiency.

“The press supplied by Nidec Arisa is the first press from this supplier and has the highest pressing force (16.000 kN) from our current presses in our plant,” he said. “The press is equipped with a microfeeder, and we are very satisfied with this equipment because it helps us to reduce material costs.”

The Arisa servo press at Magna features a six meter bed, two torque motors and double reduction with a Desch Planetary Gearbox. The press reaches 30 s.p.m. in sinus and up to 51 s.p.m. in pendulum mode.

“On this new press we will produce a very similar portfolio of products which we have been producing up to now,” Klein said. “We expect to reduce downtime during the semiautomatic die and coil change.”

Nidec Arisa is one of the most important press manufacturers for large presses focused on the automotive market. Located in Europe, Arisa designs and manufacturers mechanical, servo and transfer presses and its fully automation.

Nidec Arisa is specialized in customized designs that meets the most challenging demands from its customers. Now, focused on the E-mobility market segment Arisa is investigating and developing the latest solutions for this new and emerging market.

Nidec Arisa is part of the Nidec Press & Automation group of companies that not only offers extensive industry knowledge and experience, but also a responsive global service network. NP&A has extensive Service Centers, with spare part inventories, located on three continents, and dispatches field service personnel from more the 90 global locations.

“Worldwide customer service is very important to us, because we need to meet the requirements of our customers as efficiently as possible,” Tejkl said. “All large presses are purchased by customers to produce with high Overall Equipment Effectiveness (OEE). Production outages can significantly endanger the subsequent supply of parts to the customer and are expensive. That is why all types of services, including online services and also the supply of spare parts, are decisive for us.”

To learn more about Magna Automotive Stity and its service and capabilities, visit the company online at: www.magna-stity.cz.