They don’t make ’em like they used to. Or do they?

Heavy-duty, high quality galvanized steel pails, funnels, trash cans, and other products are still being manufactured with pride at S&K Products in Coldwater, Ohio.

An alternative to today’s plastic counterparts, S&K offers a unique line of steel ware, manufactured for a lifetime of use. In fact, owner VJ Westerheide said S&K Products is one of just two companies in the U.S. producing quality galvanized steel products.

Founded in 1949, S&K Products began by manufacturing a line of toy garden tools for children. Westerheide and his wife Marilyn purchased the company in 1989. Today, they run the family business along with their sons Brent and Kurt, and a talented workforce of 55 individuals.

Founded in 1949, S&K Products began by manufacturing a line of toy garden tools for children. Westerheide and his wife Marilyn purchased the company in 1989. Today, they run the family business along with their sons Brent and Kurt, and a talented workforce of 55 individuals.

S&K utilizes a variety of presses from the Nidec Minster Corporation including recently purchased single and double-point MMC gap presses.

Built to meet or exceed JIS Class 1 accuracy standards, the MMC Press Series features rigid fabricated steel frames to help maintain accuracy and provide increased tool life by minimizing deflection.

With precision-machined gears, counter-rotating forged steel crankshafts, and a heavy-duty wet clutch and brake, MMC Presses are designed for smooth power transmission, quiet operation and long life.

“With proper maintenance, we know the Nidec Minster presses we have purchased will still be functioning properly 25 years from now,” Westerheide said.

In addition to the attributes of the machines, Westerheide has been impressed with Minster’s responsive customer service, which not only includes field service but 24-hour technical support, repair parts, training and much more.

“Certainly a large part of our decision to purchase Nidec Minster presses is their service department,” he said. “They maintain it to high standards, with personnel that is very reliable. We know that we can always count on a rapid response if we were to have a mechanical failure.”

Some of the products manufactured by S&K can trace their roots back more than 100 years. In 1990 S&K purchased the former New Delphos Manufacturing company, which was founded in 1898, and moved the product lines to their Coldwater, Ohio facility. Today, a complete line of heavy-duty steel funnels with the “Delphos” brand are still being manufactured by S&K.

Westerheide understands the value of a high-quality product, built to last. Of the 16 Minster presses at the S&K facility, many have been in production for several decades, including an open back inclinable “No. 5” Minster press that was manufactured in 1935.

“We not only have newly purchased Nidec Minster presses, but also a variety of Minsters that are in the area of 50 years-old. They continue to be some of the top-performing presses in our facility,” Westerheide said.

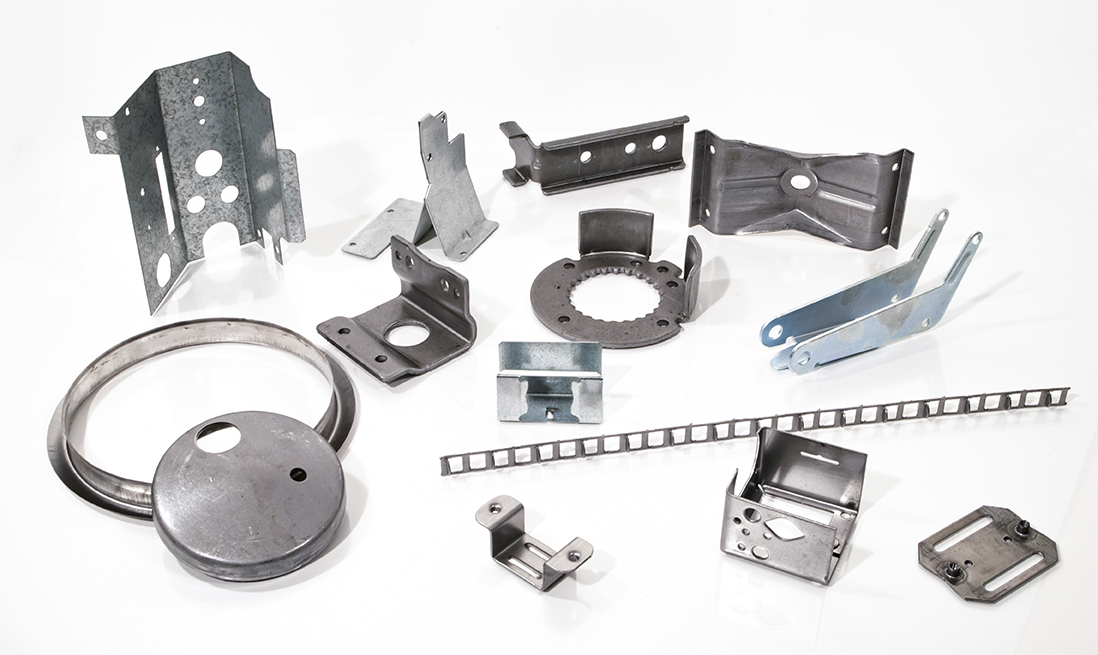

In addition to its own products, S&K manufactures contract metal stampings for other regional OEM companies, in the refrigeration, medical equipment and furniture industries, along with other specialty markets.

All S&K products proudly wear the “made in the U.S.A.” label. Many of the unique items are marketed nationally under private customer labels and are found in hardware stores and a variety of restaurant chains throughout the country.

“The ease of setup, the accuracy and the technology are all very impressive features of the Vamco Feeds, and the reason they were included with our new Minster presses,” said Scott Adams, Vice President of Operations for Brunk Industries. “I’ve always been impressed with Vamco’s products, and because of the increased production speeds, we feel they are just as valuable of an asset as the Minster presses are.”

A WORLD OF RESOURCES

A single-source solution for machinery, service and technology.