Estamode Grows With Nidec Press & Automation

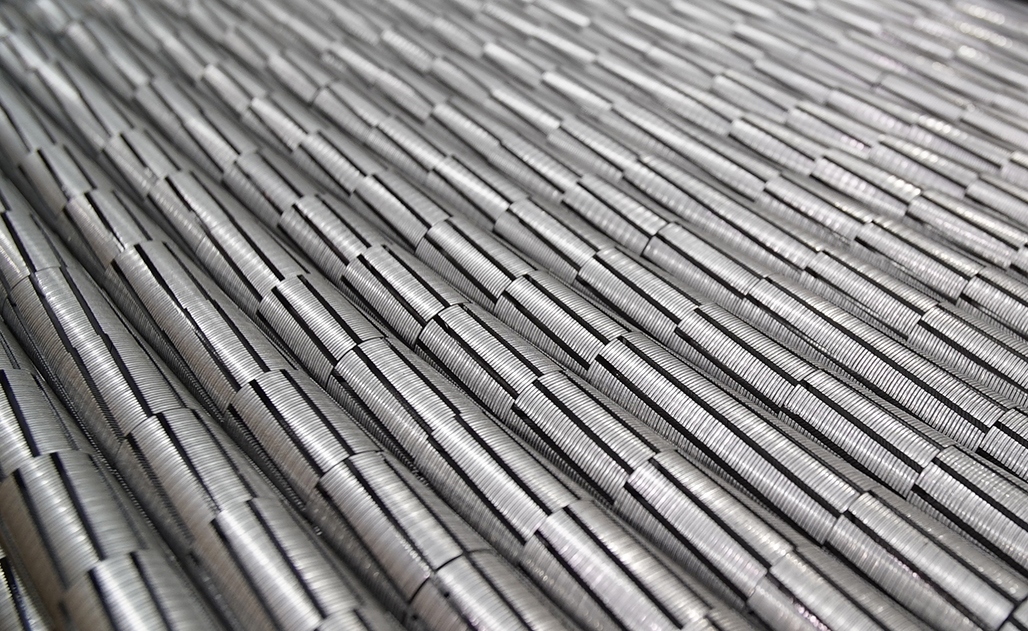

Established in 1946, Estamode has grown to one of Europe’s leading manufacturers of magnetic cores for electrical motors & generators. Located in Zaragoza, Spain, Estamode began stamping laminations in 1985, and is now a global supplier to a wide variety of industries.

In 2003, Estamode became part of the Aragonese business group SAMCA, whose activities include sectors as diverse as mining, renewable energy, food, logistics and plastic. The following year Estamode began exporting on a global level, and by 2017 the company had moved into its current modern manufacturing facility.

“Right now almost 50 percent of our turnover comes from automotive business for auxiliary motors such as solar roofs, seats, oil pumps, water pumps, and others,” said Alberto Garcia, Business Director at Estamode. “Other important business sectors are lifting, elevators and household appliances. All the products that we stamp are part of a magnetic core in an electric motor.”

Estamode is currently a valued supplier to the Nidec Corporation and continues to grow its business by delivering more added value magnetic cores, including further operations such as core insulation, winding, aluminum die casting and over-molding.

“We are focused on customer-tailored projects that includes everything from the initial steps of motor design, to serial production, and including packaging and delivery to any place in the world,” Garcia said. “Estamode is a more flexible partner for our customers than many of our competitors who are 10 times bigger than us.”

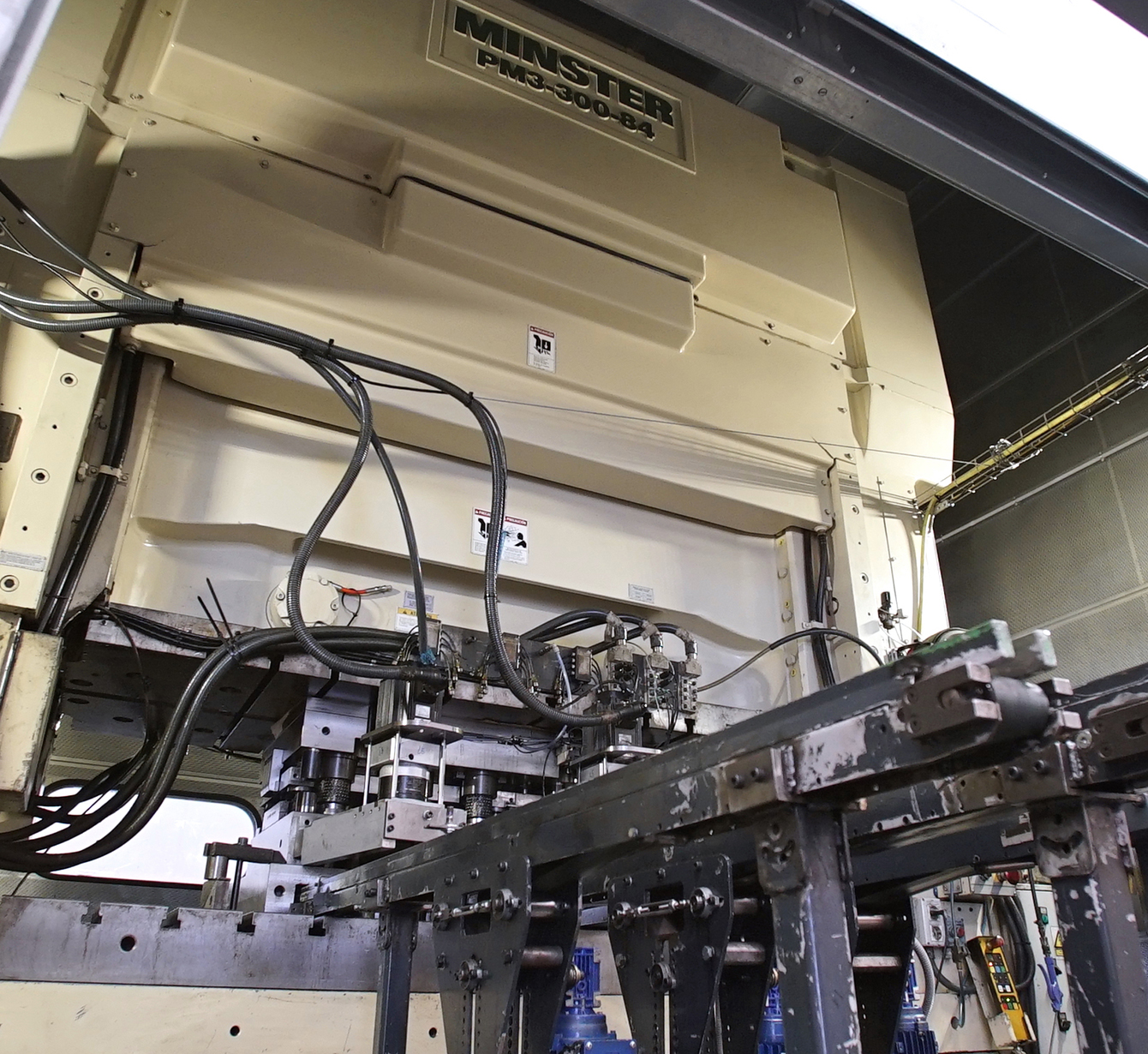

Estamode supports its project management style of business by investing in state-of-the-art technology, including high speed presses from Nidec Minster. Estamode currently utilizes seven Minster presses, including its most recent acquisition, a Minster PM4-225.

Designed for today’s high-speed lamination production requirements, the Minster PM4 Series has been configured to provide increased energy while operating at higher speeds with larger upright openings and reduced deflections.

“We’ve been working together with Nidec Minster for more than 10 years,” Garcia said. “To sum it up, Minster is the best against its competitors in the ratio of features and press cost.”

Minster’s recent expansion into the Nidec Press & Automation group of companies has also been beneficial for Estamode. By combining expertise and experience, as well as the resources and facilities of metal forming industry leaders, NP&A has created a single-source solutions for its global customers.

NP&A’s integrated brands include Minster, Arisa, Kyori, Vamco, CHS and SYS, and Estamode’s new PM4 press included a Nidec Vamco SR high speed servo feed. In addition Estamode can now utilize NP&A Customer Service and global manufacturing at nearby Nidec Arisa in Navarrete, Spain.

“For Estamode it is more reliable and comfortable to source a new press line from a single supplier,” said Miguel Marqueta, Plant Director at Estamode. “And a Service Center located in Spain will improve the technical relationship between our companies because Nidec Arisa is only one and a half hours driving from Estamode.”

Estamode is currently considering new projects, new markets and new technologies and will look toward Nidec Press & Automation as an important partner in the continued growth.

To learn more about Estamode, its products, services and unique solutions, contact the company at +34 976 46 08 88, or visit them online at www.estamode.com.